Creating a pearl inlay pen is a labor of love, combining artistic passion with meticulous craftsmanship. At every step of the process, the expert touch of skilled artisans shines through. Let’s take a closer look at how BLUSAIGON crafts these exquisite, high-end pearl inlay pens.

SELECTING THE FINEST PEARL SHELLS

At BLUSAIGON, our skilled artisans carefully handpick the finest, most vibrant pearl shells from oceans around the world, including Vietnam, New Zealand, France, Australia, and the U.S. Each shell is meticulously cleaned and sorted by size, thickness, and color to ensure only the best materials are used.

CUTTING THE PEARL/ ABALONE SHELLS

To inlay the pen, the artisan carefully cuts the pearl or abalone shells into small strips of varying sizes, tailored to the specific design requirements. This process demands precision and skill to ensure each piece is cut flawlessly and perfectly fits the pen's shape. The artisan must consider every detail to create a harmonious and aesthetically pleasing design, resulting in truly unique and intricate pieces of art.

SORTING AND SELECTING

To ensure each pen meets the highest standards of quality and craftsmanship, the artisans meticulously sort through the pearl shell strips, selecting only those that meet the strictest criteria. From thickness and compatibility with the design to color and natural patterns, only the finest pieces are chosen to create a pen that reflects elegance and excellence worthy of its user.

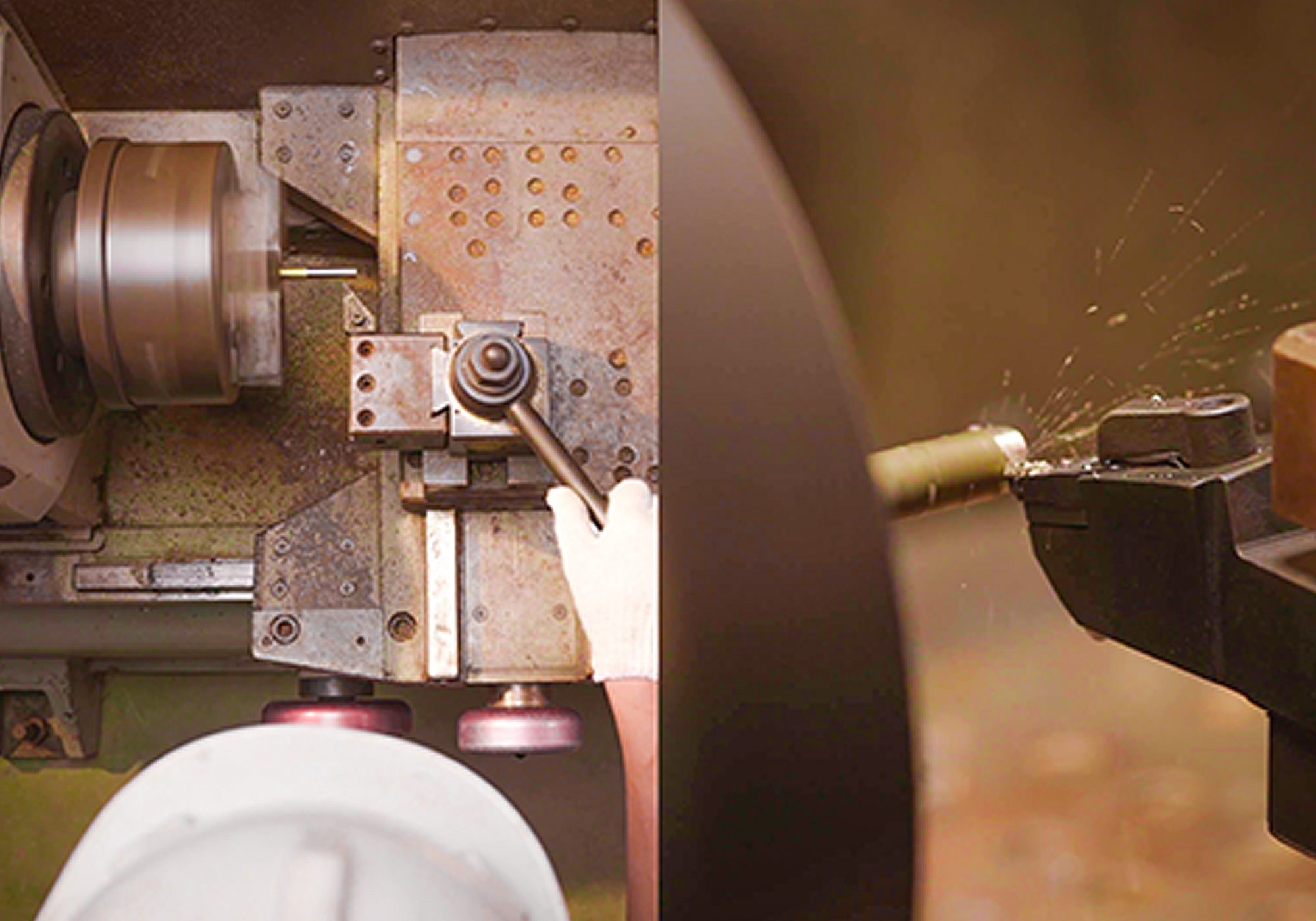

CNC CRAFTING OF PEARL INLAY PENS

The pen frame is one of the most intricate components in the crafting process. To shape the pen frame, artisans use numerous small parts, each either cast from unique molds or CNC-machined from solid brass with precision up to 0.01mm. This ensures that every design is both accurate and refined.

Once the initial frame is complete, it undergoes sanding and polishing to prepare for the next stages of crafting. This step guarantees that every detail of the pen achieves a perfect sheen, contributing to the overall elegance and luxurious finish of the final product.

ELECTROPLATING

At this stage, artisans use gold and other precious metals to electroplate the pen’s rings, adding a touch of elegance and enhancing the durability of the product. This process highlights each intricate detail, showcasing the meticulous craftsmanship and dedication that goes into perfecting every piece.

PEARL INLAYING

Once the pearl strips have been carefully cut and selected, artisans begin the intricate process of inlaying them onto the pen body. This step requires precision and attention to every tiny detail. The inlay process for each pen takes between 24 to 72 hours, while limited-edition pens can take up to 144 hours to complete. This meticulous work ensures that each pen is a masterpiece of craftsmanship and artistry.

SHAPING AND ASSEMBLING

After the pearl inlay process, artisans wait for the adhesive to fully set before moving on to shape the pen body. Using fine sandpaper, they carefully smooth the surface, sanding continuously until the pen achieves the desired smoothness, shine, and precise dimensions. This stage requires significant time to ensure perfection.

Once the shaping is complete, artisans meticulously assemble each component, ensuring every part is precisely positioned for balance and harmony. The result is a luxurious pearl-inlaid pen that radiates elegance and expert craftsmanship.

NANO COATING

Artisans apply a ceramic nano coating to the entire pen. This process prevents scratches, maintains the pen's natural shine, and improves dust resistance, ensuring the pearl inlay pen remains fresh and vibrant.

Every step is carried out with passion and precision, reflecting the artisans’ commitment to celebrating the beauty of nature and traditional craftsmanship. Ultimately, the finished pearl inlay pen is not just a writing instrument; it’s a high-value work of art that embodies elegance and meticulous attention to detail in every inlaid piece.